Engineering & Project Execution Services

The Harmony engineering team can draw on decades of experience executing projects involving AQS in a wide variety of industrial applications and , in compliance with both domestic and international codes and regulations. We have successfully engineered projects all around the world, including the Dominican Republic, Mexico, Brazil, U.S.A, Canada, Germany, Poland, France, Greece, Czech Republic, Russia, Kazakhstan, Belarus, South Africa, Egypt, U.A.E., Qatar, China, Philippines, Thailand, Indonesia, South Korea and of course India. With such a breadth and depth of experience Harmony is well equipped to handle all your engineering needs:

- Process design such as preparation of Heat & Mass Balances, PFD’s, P&ID’s and process datasheets.

- Mechanical engineering including the sizing and specification of pumps, fans, blowers, compressors and other rotating equipment, material handling and conveying equipment and various other plant machinery and static equipment.

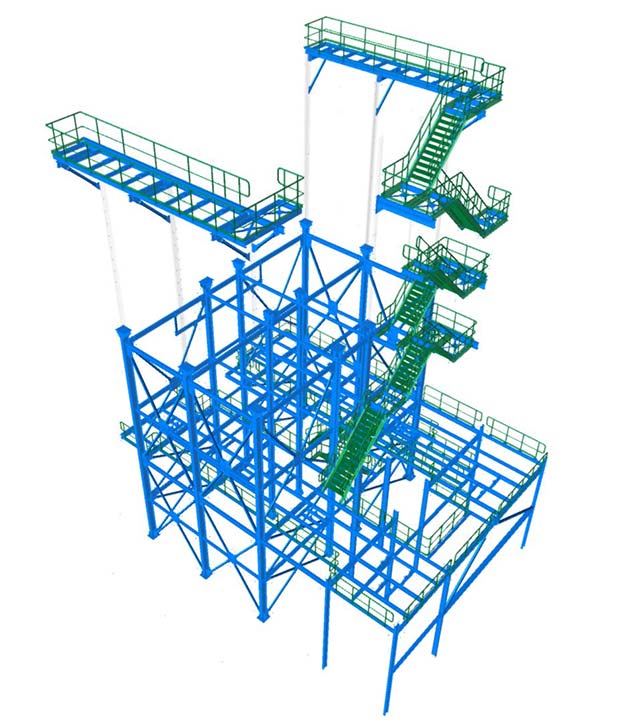

- Civil & structural design and detailing including foundation design for buildings and equipment, support and super structures for equipment, duct, equipment enclosures, pipe rack and cable tray supports and design and detailing of tanks, vessels and AQS related equipment. Our team uses a combination of in-house design tools paired with established design packages such as STAAD Pro for design activities and Advanced Steel, TEKLA and AutoCAD for detailing.

- Piping and 3D modelling capabilities include complete plant layout in 2D and 3D, pipe routing, generation of piping isometrics and orthographics and various lists, BOM’s and MTO’s related to piping and related materials. Stress analysis for ductwork and piping is carried out using CEASAR II, while modelling software packages used are Plant 3D, and E3D.

- E&I deliverables produced are single-line diagrams, cable and cable tray sizing and routing, panel design including layout and wiring details, electrical load lists, I/O list and instrument index, instrument datasheets, control valve sizing and specification, control description, logic diagrams and lighting calculations.

Leave A Comment